The role of EHS intelligent safety production management system

l The demand for more automatic and intelligent production of equipment is increasing, and more serious and dangerous industrial accidents are also prompting that wisdom and safety have emerged.

l Functions of Intelligent Safety Production Management System

Intrinsic safety of equipment-the intrinsic safety of equipment should meet the basic requirements of GB 15706/ISO 12100 risk assessment and reduction standards, GB 16855/ISO 13849 safety control system, etc. At the same time, the intrinsic safety of equipment has not been destroyed, and the industry management of people is monitored by the management platform in real time-human behavior is the most unpredictable or mandatory norm, unless there is a real-time guidance and monitoring system. And through the combination of hardware, software and management, and can grasp the phenomenon of violation in real time, people's behavior can be revised and standardized-perfect operation specification management.

Combined use function of AI Box LOTO/ intelligent LOTO security door lock

EHS intelligent safety production management platform | AI BOX intelligent security electromagnetic door lock | AI EYE early warning eye/intelligent anti-tailing early warning eye | AI Smrt LOTO/intelligent automatic |

|

|

|

|

lfacility management lrisk assessment ljob management lbehavior management lAuthorization management lStatistical analysis management | lPersonnel authorized entry/exit function lAutomatic LOTO Locking and Tagging Function lIndustrial safety door lock function lEmergency stop function lreset function | lIdentify the number of people in dangerous areas lIdentify authorized personnel in hazardous areas. lAlarm function for identifying unauthorized personnel lWhole-range tracking in the area lSafety locking function lHierarchical alarm elimination function | lMaintenance personnel authorization management lAutomatic locking of electric energy source lAutomatic identification of power state lPersonnel authorized locking/unocking. lAutomatic alarm function |

What is intelligent security

| 1. Data visualization, real-time dynamic tracking 2. The data can be analyzed and traced. 3. Establishment of large database 4. Intelligent early warning, alarm and timely stop loss |

1. Establish culture, standards and management into a dynamic early warning and alarm management system. 2. Data analysis to prevent major dangerous accidents in advance. 3. Combine management with production in real time. | |

1. People's execution: the operating frequency and behavior records of employees. 2. Equipment implementation: hardware inspection, repair, early warning and alarm. 3. Everyone should work in a unified way and put an end to one person and one behavior. |

Modularization of EHS intelligent safety production management system

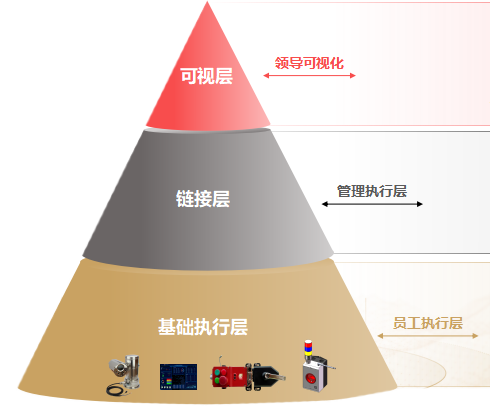

l Starting from the four units of man-machine environmental management, various risks existing in safety production are identified, evaluated and pre-controlled, especially on-site operation behavior control, to ensure personal and equipment safety, and to achieve all-round, whole-process, all-weather three-dimensional control of safety production.。

l You can choose the module for application according to the actual situation of the factory.

l You can put forward various requirements for development and customization.

l We can also develop with you.

This safety management system mainly includes the following functional modules: | |||

| 1、facility management | 2 、Standard management | 3、risk assessment | 4、Forklift management |

5、SOP job management | 6、Safety inspection management | 7、Early warning and alarm management | 8、Report management |

9、Supplier management | 10、Factory management | 11、debugging | 12、Environmental management |

13、Maintenance call system | 14、Regional management | 15、Authorization management | 16、Accident management |

17、Management of major hazard sources | 18、Hidden danger investigation | 19、Fire control management | 20、Accident investigation |

21、Safety training | 22、Hazardous chemicals management | 23、Violation management | 24、occupational health |

Lihong Safety Equipment Engineering (Shanghai) Co., Ltd.

E-Mail: info@lh-safety.com

Address: 581 Xiuchuan Road, Chuansha Town, Pudong New District, Shanghai

(Greenland East Coast International Plaza-Room A 313)

Copyright ? Lihong Safety Equipment Engineering (Shanghai) Co., Ltd. ICP19034341-1 Technical Support: lanjujing